MicroLogix 1500 Controllers

MicroLogix 1500 is an invaluable and powerful addition to the MicroLogix family of programmable controllers. Due to its features, it can be regarded as one of the signature products of Allen Bradley/Rockwell Automation. It is a compact yet expandable controller which has a very small footprint even after expansion. Its compactness accompanies cost-effectiveness which makes it even more demanding. Robustness, compatibility with a large range of communication protocols, and easy programmability stand as other important features of MicroLogix 1500 programmable controllers. This brief article provides an insight into only the major and important features of MicroLogix 1500 controllers.

Hardware and Mechanical Features

The processor and base unit can be taken as two main components of MicroLogix 1500 controller hardware. The base unit of the MicroLogix 1500 controller houses input and output circuitry, a power supply, and also the processor (which is detachable). Equipped with removable terminal blocks, it can be expanded using a compact I/O module. It also has I/O indication LEDs, Status LEDs, a memory module, and a communication port apart from other little accessories required to support its various functionalities.

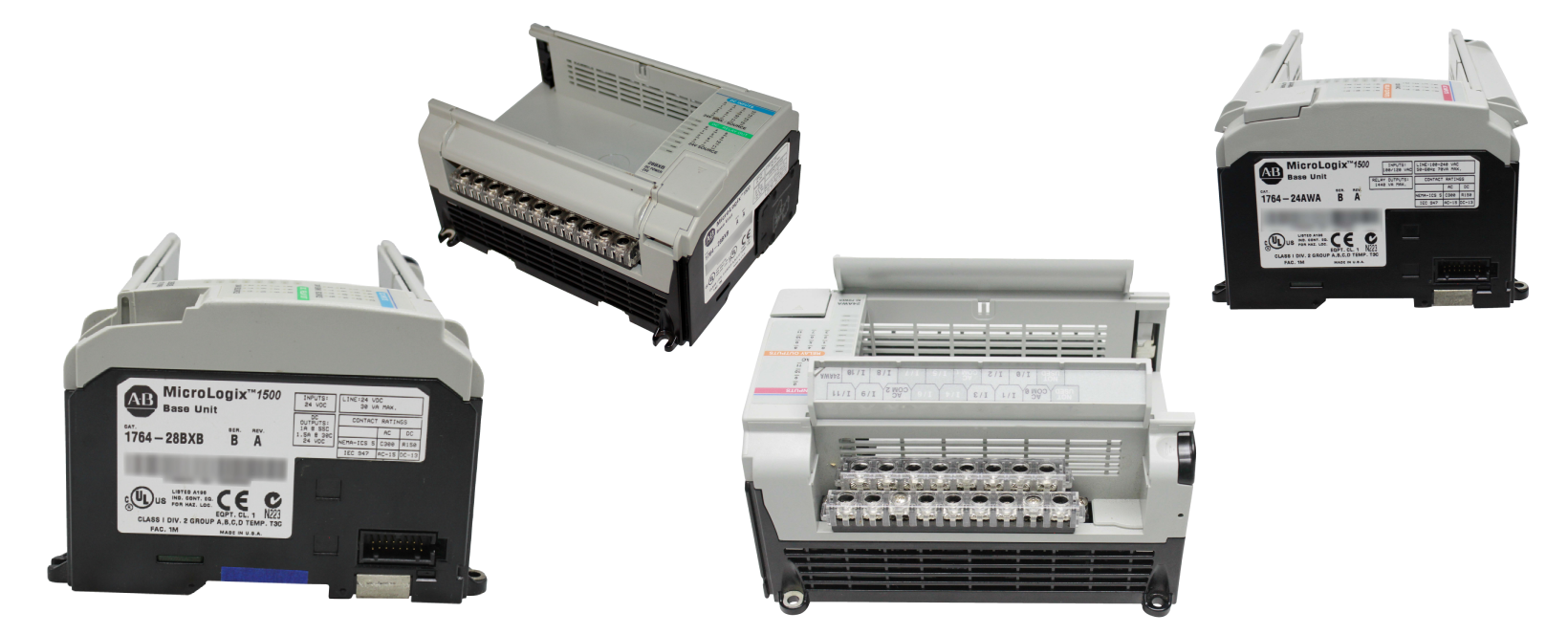

Base Unit

MicroLogix 150 family controllers could have one of these three types of base units: 1764-24AWA, 1764-24BWA, and 1764-28BXB.

These base units have variations based on their supply line power (AC or DC), type of input and output pins (AC or DC), and availability or non-availability of high-speed input/output pins. These variations are discussed in the respective topics.

Dimensions, Sizing, and Mounting

MicroLogix 1500 programmable controllers are quite small in size but support features that were previously supported by large-sized controllers only. Even after using a portable expansion I/O module, its size remains small and its footprint, little. All three types of base units have just 87mm depth, 168mm width, and 138mm (if the DIN latch is open) or 118mm (if the DIN latch is closed) height.

The base unit, which is a primary component of the controller, is designed for horizontal mounting. If the user needs to install expansion modules, they will lie on the right side of the controller. For prolonged life of the controller and hazard-free performance, 50mm must be spared on each side of the base unit to allow proper ventilation. Furthermore, the base unit and expansion I/O bank are locked into each other via DIN rail latches. These locked components can, then, be mounted or removed together from the DIN rail.

Allen Bradley specifies that this controller unit is suitable for use in a non-hazardous environment. More specifically, it is recommended for use in Class I, Division 2, Groups A, B, C, and D. Moreover, to protect the controller from harmful contaminants or corrosive environment, the unit must be used in an enclosure. The user might need to use an air conditioner to keep the controller circuitry cool.

I/O Ports

Allen Bradley’s series of MicroLogix 1500 programmable controllers have 24 or 28 I/O ports.

MicroLogix 1500 controller 1764-24AWA base unit has 12 input pins which are essentially 120V AC ports. Its output pins are also 12 which are relay outputs having 2 isolated relays per unit. Anyhow, this base unit doesn’t contain any high-speed I/O (Input/Output) pin.

MicroLogix 1500 controller with 1764 - 24BWA base unit is also equipped with 12 input and 12 output pins. Among input ports, 8 are standard 24V DC pins, while 4 are fast 24V DC pins that operate at 20 a kHz input signal. Output pins of this unit are also relay-based with 2 isolated output relay pins.

1764-28BXB base unit for MicroLogix 1500 programmable controller has 28 I/O ports contrary to other 2 base units. Among its 16 input pins, 8 are standard 24V DC ports, and the final 8 are fast 24V DC ports. As far as output ports are concerned, it is the only unit that houses FET (Field Effect Transistor) transistor outputs. This unit has 6 relay-based outputs; two of which are isolated relays. 4 output ports of this base unit are standard 24V DC FET based and 2 are fast 24V DC FET based pins. Fast input and output ports have an operating frequency of up to 20kHz.

Expansion Modules

To provide application flexibility while maintaining a small size and small footprint of the controller, MicroLogix 1500 supports the option of using an I/O expansion module. After the addition of the expansion module, the controller can have up to a total of 128 I/O ports. This module can be installed or replaced easily and quickly from the front of the unit. These compact expansion modules contain 120/240V AC I/O ports, 24V DC sink/source ports, AC/DC relay ports, and analog I/O ports.

Depending upon system specifications, a maximum of eight or sixteen I/O expansion modules can be connected with one MicroLogix 1500 controller. One I/O bank is connected to the controller directly and the other is connected via a cable. A 1760 expansion cable is used to make a connection and a maximum of one cable can be attached with one controller. Anyhow, each expansion module requires its own power supply to operate. The first expansion module uses an embedded power supply of the controller.

To support I/O expansion banks, a system with specified characteristics must be used (like processor requirements are discussed in the processor section briefly).

Processor

The processor unit in MicroLogix 1500 programmable controllers is detachable easily from the base unit so it can be removed and replaced without disturbing existing wiring configurations. The processor unit could be 1764-LSP or enhanced 1764-LRP. In the case of catalog number 1764 – LSP, more than 7K user memory is available, while in the case of catalog number 1764 – LRP, the user memory is 12K.

To add further, 1764 – LRP is equipped with an RS-232 communication port and features 30V DC isolation. If any type of I/O expansion module is to be used with MicroLogix 1500 controllers then processors need to fulfill specific requirements.

Data Access Tool (1764-DAT)

It is a very useful accessory that comes with MicroLogix 1500 programmable controllers. It facilitates users to access 48-bit elements directly and easily. This access could also be to 48 integer elements. It is equipped with two function keys. This accessory tool has one display screen to show controller faults. It can be removed from the unit or inserted back into it while power is on.

Memory Module and Real-time Clock

Depending on the level of functionality, there is a range of modules available which can be used with MicroLogix 1500 programmable controllers. Their distinction based on function and memory size is as follows.

- 1764-RTC has a real-time clock, but the memory option is not applicable to it

- 1764-MM1 has a memory module with a size of 8K

- 1764-MM1RTC has a real-time clock and a memory module with a size of 8K

- 1764-MM2 has a memory module with a size of 16K

- 1764-MM2RTC has a real-time clock and a memory module with a size of 16K

- 1764-MM3 has a memory module with a size of 16K

- 1764-MM3RTC has a real-time clock and a memory module with a size of 16K

1764-MM3xxx module is capable of saving recipe data of Data Log Queue. Apart from this, there exists no difference in functionality between the two types of modules. They also have the same memory size.

The memory module is to provide a way for transporting some data or a program file in a very simple manner. This function brings flexibility and ease as the user will not need the use of some programming software or a PC (Personal Computer) for the purpose. Anyhow, just one program can be stored in a memory module at a time. The memory module also has a program compare function which helps enhance application security.

An RTC (Real Time Clock), as well as a memory module, can be inserted or removed into the controller without causing any damage to the controller and module even if the controller is in executing mode. Anyhow, removal of RTC and insertion of memory module is detected when the controller goes into its non-executing mode or one power cycle elapses.

Electrical Characteristics

Line Power

Three mentioned base units might take AC or DC input within specified limits. For safer operation, Allen Bradley has specified the line voltage range for all three types of units. Nominal voltages, frequencies, and operating ranges for these base units are as follows:

- 1764-24AWA (120/240V AC nominally, 85 to 265V AC at 47 to 63Hz)

- 1764-24BWA (120/240V AC nominally, 85 to 265V AC at 47 to 63Hz)

- 1764-28BXB (24V DC nominally, 20.4 to 30V DC operating window)

Power Supply

Allen Bradley recommends choosing the power supply rating according to applications. MicroLogix 1500 controllers feature an internal capacitor that should be charged upon power-up and thus power source must be capable of providing inrush current to charge the capacitor. Anyhow, if the power source would not be able to supply this inrush current, voltage sag will be observed momentarily, and the charger will get charged slowly.

Furthermore, Allen Bradley has designed the power supply coming in the MicroLogix 1500 controller package to withstand a brief power loss while not affecting the operation of the system. This time during which the power supply keeps the system operational after power loss is termed as “program scan hold-up time after the loss of power”. This hold-up time provided by a power supply can go up to 3 seconds starting from 10 milliseconds. Factors like state and type of I/O port affect this timing. After this time, the processor is signaled non-availability of enough power to the system so the processor could perform a shutdown of the controller in an orderly manner.

More importantly, generally, power supply hold-up time is kept more than the turn-off or turn-on timing of input ports. This factor is taken into account when the program is written.

Communication Compatibility

Allen Bradley’s MicroLogix 1500 controllers support a wide range of communication protocols. The base unit has a communication port (channel 0) for the purpose, and it can be configured for any desired communication protocol which is supported by the controller. 1764-LRP type processors are equipped with one additional communication port referred to as Channel 1. This port can also be configured independently of channel 0 for any supported communication protocol. Communication protocols being supported by these controllers are listed here:

- A personal computer can be connected to these controllers.

- Through an AIC (Advanced Interface Converter), this controller can be connected to the DH-485 network. This network supports a multi-master option and has the capability to provide interconnection for up to 32 devices (where any node or many nodes can be added or removed from the connection network without disrupting the whole of it).

- Using an Ethernet Interface Module like (1761-NET-ENI), MicroLogix 1500 controller can be connected to an Ethernet network.

- These controllers also support communication with DeviceNet networks through a DeviceNet Scanner module

- As a Remote Terminal Unit (RTU) slave, this controller can be connected to Modbus SCADA (Supervisory control and data acquisition) networks. Using Modbus protocol, one master device can communicate with up to 255 different slave devices.

The processor unit received from the manufacturer has a default communication configuration present which is detailed by Allen Bradley. If the user has changed the default configuration parameters and wants to switch back to default ones, it can be done using a Communication Toggle Push Button which is made available on the processor (This button affects Channel 0 configuration parameters only and not that of Channel 1). An LED is specified on the processor to show if Default Communications (DCOMM) mode is in work at some moment.

As the communication port of these controllers provides for the RS-232 interface and is meant for serial binary communication. It provides the user an opportunity to use any serial mode of communication from the provided list. A communication channel can be configured for Full-Duplex communication whereby a serial cable can be used to connect the serial port of the PC with that of the controller. DF1 Full-Duplex configuration fits best when point-to-point serial communication is needed. A PC can also be connected with several controllers while using the DF1 Half-Duplex communication protocol.

Rs-232 also facilitates users to integrate radio modems or telephone sets into your control system.

Electromagnetic Compatibility (EMC)

MicroLogix 1500 programmable controllers are designed to work for a range of applications including those which need high-frequency operations. Thus, the electronic module in the controller is designed such that noise is kept nil or minimized to avoid interference issues. As this controller is designed specifically to work for industrial applications so it is made to meet EMC standards pertaining to the industrial environment. Some of the standards or parts of standards, satisfied by MicroLogix 1500 controllers, are:

- Council Directive 89 / 336 / EEC

- EN 50081-2: This is the EMC generic emission standard. Part 2 of this standard is for the industrial environment.

- EN 50082-2: This is also the EMC generic immunity standard. Part 2 also focuses on the industrial environment.