1794 FLEX I/O Selection Guide

The 1794 FLEX I/O is a small, modular, distributed I/O system from Allen-Bradley/Rockwell Automation. It offers all the functions of larger rack-based I/O platforms for distributed control applications, with minimal space requirements. 1794 FLEX I/O systems complement all other controller platforms from Rockwell Automation for a distributed I/O solution.

Benefits

The Allen-Bradley 1794 FLEX I/O system offers the following benefits:

- Reduced Space Requirements: It eliminates the need for multiple long wiring, as direct-wired connections can be made from the field devices to the terminal base. This helps in reducing wiring terminations, engineering and installation costs, system setup time, and downtime.

- AdvancedFunctionality: 1794 FLEX I/O systems provide a wide range of functionalities, with 2-point to 32-point I/O modules providing all the functions of larger rack-based I/O systems.

- Increased Productivity: 1794 FLEX I/O modules are easy to configure and set up using wizard speeds for engineering and installation purposes.

- Operation in Harsh Environments: 1794 FLEX I/O-XT modules are conformally coated for use in extreme environments. For instance, while non-XT FLEX I/O modules operate within temperature ranges of 0 °C to 55 °C (32...131 °F), FLEX I/O-XT operate reliably within -20 °C to 70 °C (-4...185 °F) temperatures.

- Reduced Downtime: The Removal and Insertion Under Power (RIUP) and module-level diagnostics features of 1794 FLEX I/O systems eliminate unnecessary downtime.

- Exceptional Multiple Choices: The 1794 FLEX I/O system provides you with more than 90 varieties of digital and analog I/O modules and breadth of specialty modules to meet the needs of a wide variety of control applications.

- Network Functionality: The FLEX 1794 I/O system can communicate on EtherNet/IP, DeviceNet, ControlNet, and several other open networks such as Remote I/O, Interbus-S, and PROFIBUS DP.

- Improved Plant Operations: HART analog FLEX I/O modules allow transmission of HART data to controllers or asset management software. This greatly improves plant operations.

Overall, the cost-effectiveness, modularity, network flexibility, and reliability of the 1794 FLEX I/O system have made it one of the most popular distributed I/O controller platforms on a global scale.

System Design

A typical design of a 1794 FLEX I/O system consists of modular components that mount onto a DIN rail or snap together to form the 1794 FLEX I/O assembly. These modular components include:

- Adapter Module: A 1794 FLEX I/O adapter module is used to provide a communication interface between a scanner port and FLEX I/O modules across an I/O link.

- Terminal Base: This contains a terminal strip that provides terminal connection points for I/O wiring and terminates wiring between two or three field devices. Each 1794 FLEX I/O module has a terminal base that snaps onto the DIN rail to the right of the communication adapter. 1794 FLEX I/O terminal bases plug together to form the backplane, which provides connections between the I/O modules and an adapter module.

- I/O Module: This module has the bus interface and circuitry required to perform specific I/O functions concerning your application. 1794 FLEX I/O modules plug into a terminal base and connect to the I/O bus and field devices. The Removal and Insertion Under Power (RIUP) feature make it possible for you to replace a failed FLEX I/O module without disrupting system power, the field wiring, or other I/O modules.

- Power Supply: The Adapter/power supply in a 1794 FLEX I/O system powers the internal logic of as many as eight 1794 FLEX I/O modules.

- Accessories: These provide the 1794 FLEX I/O system with added application flexibility. They include panel mount kits and extender cables.

Selection Criteria

Outlined below are the steps to follow as you specify your 1794 FLEX I/O system:

Select a Communication Network

Choose an appropriate communication network based on your application requirements. For example, you can configure your 1794 FLEX I/O system for information exchange between a specific scanner and a range of field devices. As previously stated, a 1794 FLEX I/O system can communicate on the following networks:

- EtherNet/IP: This is an open industrial networking standard that supports explicit and implicit messaging. It makes use of commercial, off-the-shelf physical media and Ethernet equipment.

- ControlNet: It enables intelligent, high-speed control devices on the factory floor to share the information required for programming, remote device configuration, troubleshooting, supervisory control, operator interface, and work-cell coordination.

- DeviceNet: This network allows high-speed access to plant-floor data from a wide range of factory floor control devices. It also provides a considerable reduction in wiring.

- Other Open Networks include PROFIBUS DP, Remote I/O, and many others from Encompass partners.

In addition, Rockwell Automation 1794 FLEX I/O systems support the Common Industrial Protocol (CIP). The CIP protocols enable complete integration of control with information networks, standard Internet technologies, and multiple CIP networks.

The aforementioned communication networks (EtherNet/IP, ControlNet, and DeviceNet) share the Common Industrial Protocol at their upper levels while being media-independent at their lower levels. Therefore, you can specify the best CIP network for your application and eliminate the need for complex and costly network gateways, when connecting different upper-level networks.

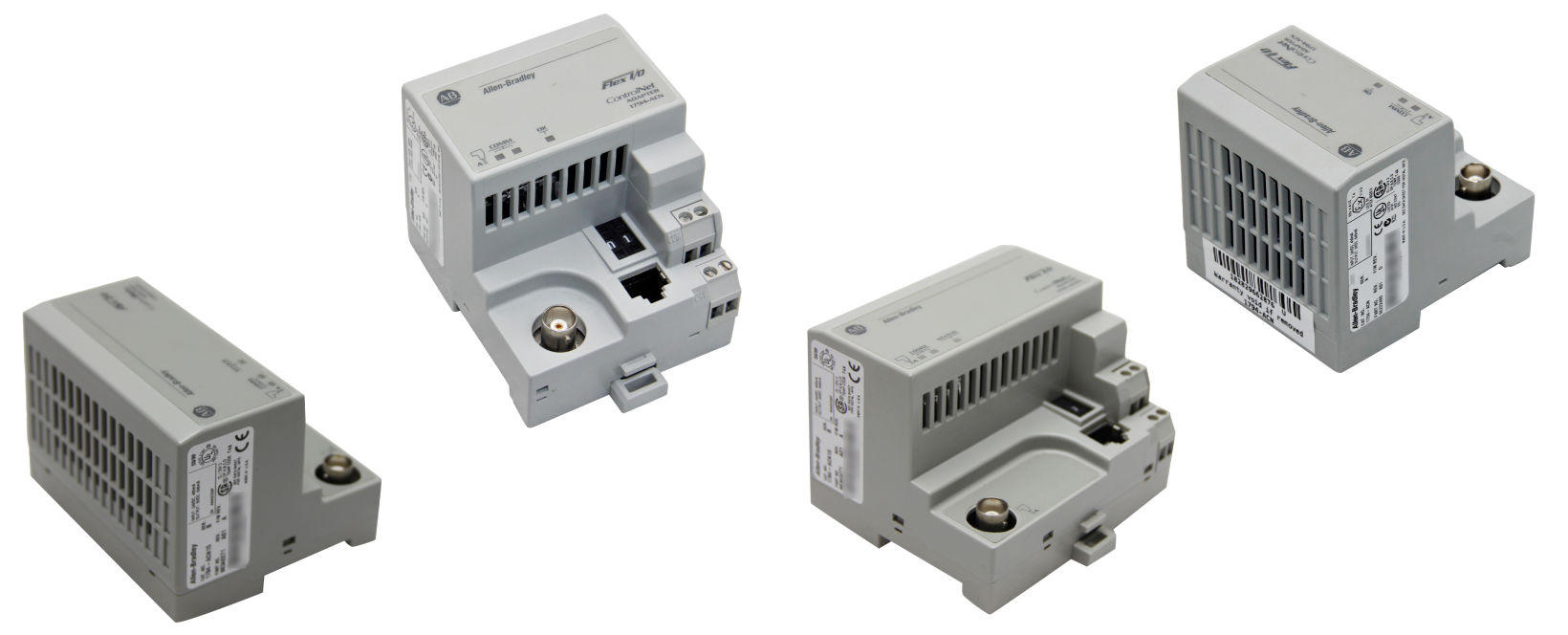

Select a Communication Adapter

After selecting the networks that meet your application’s communication needs, you should select the appropriate communication adapters for those networks. A 1794 FLEX adapter module interfaces FLEX I/O modules and other system components across a communication network. The adapter communicates with the FLEX I/O modules over a backplane. It consists of an integrated power supply that converts 24 V DC to 5 V DC, for the backplane to power the connected FLEX I/O modules.

1794 FLEX I/O communication adapter modules are available for DeviceNet, ControlNet (redundant or single media), EtherNet/IP (dual- or single-port), and PROFIBUS DP. The table below provides an example of the selection criteria for communication networks and appropriate FLEX I/O adapters, to meet specific application needs.

-

EtherNet/IP

-

Application Requirements:

- Plant operations such as material handling

- Data collection, configuration, and control on a high-speed network

- Time-critical applications without a set schedule

- Frequent sending of data

- Internet/Intranet connections

- High availability network requirements, a built-in switch (dual-port AENTR)

-

Communication Adapter:

- 1794-AENT

- 1794-AENTR

- 1794-AENTRXT

-

Application Requirements:

-

ControlNet

-

Application Requirements:

- High-speed transmission of time-critical data between FLEX I/O devices and controllers

- Repeatable and Deterministic data delivery

- Media redundancy

-

Communication Adapter:

- 1794-ACN15

- 1794-ACN15K

- 1794-ACNR15

- 1794-ACNR15XT (for FLEX I/O-XT)

-

Application Requirements:

-

DeviceNet

-

Application Requirements:

- Connecting low-level devices to factory floor controllers

- Advanced diagnostics for improved fault detection and data collection

- Reduced wiring and less start-up time compared to traditional, hard-wired systems

-

Communication Adapter:

- 1794-ADN

- 1794-ADNK

-

Application Requirements:

-

Remote I/O

-

Application Requirements:

- Connecting to Remote I/O networks

-

Communication Adapter:

- 1794-ASB

- 1794-ASB2

-

Application Requirements:

-

PROFIBUS DP/PROFIBUS DPVI

-

Application Requirements:

- Connecting to PROFIBUS DP and PROFIBUS DPV1 networks

-

Communication Adapter:

- 1794-APB

- 1794-APBDPV1

-

Application Requirements:

Select FLEX I/O Modules

To determine which 1794 FLEX I/O module will best suit your application requirements, you’ll need to specify the following:

- What type of application will the 1794 FLEX I/O be used for?

- What field devices are being connected?

- The location of the field devices and the number of points needed.

- The number of points available per FLEX I/O module.

- The number of FLEX I/O modules required.

The choices and flexibility you have with 1794 FLEX I/O modules range from discrete and analog modules to motion and temperature control for a distributed system I/O solution. This flexibility provides you with the following possible choices of I/O signal types:

- Digital: DC and AC voltage signals

- Analog: voltage or current

- Relay: Normally Open(N/O), with 2A(Amperes) capability

- Protected Outputs: Latching, non-latching, and with diagnostics

- Temperature Control: RTD or Thermocouple

- Motion Control: Flow metering, High-Speed Counters, and Totalization

- Combo Modules: Combination of either digital or analog input and output capabilities

- Harsh Environments: Use of FLEX I/O-XT in harsh industrial environments

- Intrinsic Safety (IS): Use of 1794 FLEX Ex I/O to connect to field devices in hazardous areas

The available 1794 FLEX I/O modules are broadly classified into three categories, from which you can choose. These include:

- 1794 FLEX I/O Digital Modules: They cover a broad electrical range, with different densities ranging from 8 up to 32 points. Also, protected outputs, isolated inputs or outputs, Diagnostics, and Electronic fusing are available on some of these digital modules. Digital FLEX I/O modules interface with a variety of field devices such as limit switches and pushbuttons, relay contacts, and ON/OFF actuators like pilot lights, motor starters, and annunciators.

-

1794 FLEX I/O Analog Modules: These modules provide (i) Channels that are individually configurable. (ii) Selectable input filters on most of the modules. (iii) On-board scaling. (iv) Internal calibration which is performed in the 1794-IE8, 1794-IE4XOE2, and 1794-OE4 modules. (v) HART (Highway Addressable Remote Transmitter), RTD and Thermocouple modules are also available in this category. You can choose 1794 FLEX I/O Analog Modules when you need:

- Individually configurable channels to use with a variety of sensors.

- On-line configuration for changing the system’s configuration while in operation. Analog modules with this feature can be configured in RUN mode, using the control program or programming software.

- Selectable input filters to select the operational frequency for each channel that best meets the performance requirements of your application from various filter frequencies. Higher filter settings provide much faster performance, while lower filter settings offer higher resolution and greater noise rejection. Note: The thermocouple module provides you with ten filter selections, isolated analog FLEX I/O modules have four filter selections, and the combined RTD/thermocouple module has eight filter selections.

- To direct output device operation in case of an abnormal condition.

- Selectable response for a malfunctioning or broken input sensor. With this feature, you can specify a corrective action for a given channel condition, based on the feedback sent to the controller.

- Differential or Single-ended inputs depending on the module used. Isolated analog temperature modules provide differential inputs, while standard 1794 FLEX Analog modules provide single-ended inputs. Single-ended inputs such as voltage sensors are less expensive. On the other hand, differential inputs are more expensive, but they are usually more immune to electrical noise.

-

1794 FLEX I/O Specialty Modules: These include (i) Frequency modules. (ii) Very High-Speed Counter modules. (iii) Pulse Counter modules. To decide which 1794 FLEX I/O specialty module will best meet your application needs, you’ll have to identify the following:

- The type of application the specialty module will be used for

- The field devices, signal types, and signal levels to be connected to the specialty module

Note: All 1794 FLEX I/O modules plug into the terminal base, that connects to the I/O circuitry and an interface bus.

Select a Terminal Base Unit

Choose an appropriate terminal base unit for your 1794 FLEX I/O modules. You can use up to eight terminal bases per communication adapter. This allows a wide array of I/O channels per adapter, providing a maximum of 96 analog modules or 256 digital I/O with 32-point modules per adapter. Also, the terminal bases allow you to mix and match analog, digital, and specialty FLEX I/O modules with mounting and wiring options, to meet your specific application needs.

The FLEX I/O wiring terminations are carried out almost entirely on the terminal base unit. Hence, external terminal blocks are not required. Selection of wiring terminations for terminal bases includes cage-clamp, screw-clamp, and spring-clamp to directly wire 4-, 3-, or 2- wire devices. Additional terminal base options such as knife disconnect, fused, and D-shell terminal bases are also available. You should also select an appropriate adjustable key switch to prevent the incorrect insertion of a FLEX I/O module into a pre-configured terminal base.

Note: You can exchange Terminal bases in your 1794 FLEX I/O system without moving other bases. The following information outlines some of the available 1794 FLEX I/O terminal base units, from which you can choose.

- 1794-TB2: 2-wire Cage Clamp

- 1794-TB3: 3-wire Cage Clamp

- 1794-TBS, 1794-TB3TSK: 3-wire Spring Clamp

- 1794-TBKD: Cage Clamp Knifeswitch Disconnect

- 1794-TBKDS: Spring Clamp Knifeswitch Disconnect

- 1794-TBN, 1794-TBNK: Screw clamp Terminal Base Unit (NEMA-style)

- 1794-TBNF: Fused Terminal Base Unit (NEMA-style)

- 1794-TB37DS: 37 Pin D-Shell Termination (analog & digital modules)

- 1794-TB62DS: 37 Pin D-Shell Termination (analog & digital modules)

- 1794-TB62DSG: 62 Point Grounded D-shell (analog modules)

- 1794-TB62DST: 62-Pin D-shell Termination

Note: The suffix “K” in some of the catalog numbers indicates conformal coated versions of standard terminal bases. Such terminal bases can be used with 1794 FLEX I/O-XT (extended temperature modules).

Select a Flex I/O Power Supply

The 1794 FLEX I/O modules are powered by the integrated 24V DC adapter/power supply via the backplane. If the power consumption of your 1794 FLEX I/O system exceeds the maximum rating of the in-built power supply, you can install additional external power supplies. In such a case, choose an appropriate FLEX I/O power supply, to ensure sufficient power flow to the I/O modules and communication adapter.

You can power a 1794 FLEX I/O system with a FLEX power supply, or any other compatible power source such as a 1606 switched-mode power supply. The available FLEX power supplies include:

-

1794-PS3

- Input Voltage (nominal): 120V/22V AC

- Input Power: 86 W

- Output Current (Max.): 3.0 A

-

1794-PS13

- Input Voltage (nominal): 120V/22V AC

- Input Power: 36 W

- Output Current (Max.): 1.3 A

Determine the Mounting Requirements

You can vertically or horizontally mount your 1794 FLEX I/O system on a standard 35 mm (millimeter) DIN rail. You can also decide to panel-mount the system. Therefore, to identify the mounting requirements of your 1794 FLEX I/O system, you should specify the following:

- DIN rail mount or Panel Mount.

- The appropriate number of DIN rails or panels required based on the system’s physical requirements and the number of I/O modules used.

- Whether or not an end cap is required per the controller system.

Select Optional Accessories

Choose the appropriate accessories that can enhance the performance and flexibility of your 1794 FLEX I/O system. Allen-Bradley/ Rockwell Automation provides a variety of Accessories for use in 1794 FLEX I/O systems. These accessories are as outlined below:

- 1794-CE1: Extender Cable, 1 ft.( 0.3 meters)

- 1794-CE3: Extender Cable, 3 ft. (0.9m)

- 1794-CJC2: Cold Junction Compensator Kit

- 1794-N2: FLEX Dummy Filler Module

- 1794-NM1: Panel Mounting Kit

- 794-LBL: Label Kit for terminal base units

- 1492-EA35: DIN Rail Locks (for vertical mounting)